GLASS SHOWER FAQS

Frequently Asked Questions

Frequently Asked Questions

- Which Frame Finishes are Currently Most Popular?

- What is the Difference Between Frameless and Semi-Frameless?

- What is the Difference Between 3/8″(10mm) and 1/2″ (12mm) Shower Glass?

- Can a Frameless Shower be Designed to be Leak Proof?

- Can Centennial Remove My Existing Shower Before Installing a New One?

- What is a Frameless Glass Shower Transom?

- What is the Difference Between Low-iron and Clear Glass?

- What Is Tempered Shower Glass?

- What are Typical Guidelines for Measuring?

- What Does “Plum” and “Out of Plumb” Mean?

- What if My Wall, Floor or Ceiling Isn’t Plumb?

- How Long Will it Take to Manufacture My Shower?

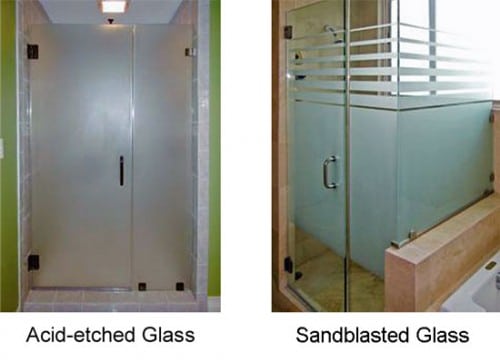

- What is the Difference Between Acid-Etched Glass and Sandblasted Glass?

- What is a U-Channel?

- What’s the Difference Between a Pivot Hinge and a Side-Mount Hinge?

- Is a Pivot Hinge Shower Door Less Expensive Than a Side-Mount Hinge Shower Door?

Which Frame Finishes are Currently Most Popular?

What is the Difference Between Frameless and Semi-Frameless?

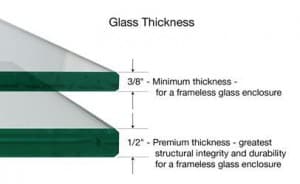

What is the Difference Between 3/8″(10mm) and 1/2″ (12mm) Shower Glass?

Premium 1/2″ (12mm) glass offers the greatest structural integrity and durability. Being the same kind of glass that’s used for storefronts, it not only looks more impressive but also has a more substantial feel.

Can a Frameless Shower be Designed to be Leak Proof?

Fixed glass panels are sealed at the base of the floor and along the sides with clear silicone sealant. With proper design and installation, these areas will not have problems with water leakage.

Most water seepage issues stem from the door which requires a minimum clearance space of 1/4″ along the top, bottom, and opening side. Here there are several ways to minimize or prevent water leakage:

- Install a shower sweep with drip rail onto the bottom of your frameless glass shower door. This will tighten up the clearance space under the door and prevent water seepage.

- Add a back sweep to the rear of the door (a clear vinyl seal mounted with hi-bond tape).

- Use a doorstop. Centennial sells clear polycarbonate doorstops that fit over the edge of an adjacent glass panel with a lip that extends out to catch the frameless shower door to prevent it from swinging into the shower. By catching the door, doorstop temporarily closes clearance space along the door opening.

- Do not direct water spray at the frame-less shower door. Protective seals improve water-tightness but a glass shower is not like an aquarium. Although we seal door hinges to give them a protective coating, the hinges aren’t waterproof.

- Do not neglect replacing seals. With regular use, over time sweeps and stops will need replacing just as car seals and hoses do. If your frameless glass shower suddenly becomes less watertight, the first step in trouble-shooting will be to check the seals.

Can Centennial Remove My Existing Shower Before Installing a New One?

Please note that Centennial does not remove or install shower trays or bathtubs. This needs to be completed ahead of time by another party.

What is a Frameless Glass Shower Transom?

Common applications for using a glass transom include:

- Stabilizing tall floor-to-ceiling showers. Homeowners who want a floor-to-ceiling frameless shower may need a glass transom in their design. The need depends on ceiling height and weight limit of the shower door.

- Installing pivot doors. Pivot doors that don’t run floor-to-ceiling can mount to a header or a glass transom. Homeowners who would like to avoid the framed look of a header may find a solution by revising their design to incorporate a glass transom.

- Venting steam showers. Steam showers must run floor-to-ceiling for an airtight construction so steam can accumulate. Instead of brining the door all the way to the ceiling, most steam showers are designed with movable transoms above the door. The glass transom then acts as a vent to be tilted open to release hot steam when it’s time to cool down.

What is the Difference Between Low-Iron and Clear Glass?

However, manufacturers have now devised a method to remove most of the iron particles from glass to provide excellent clarity and true color representation for bathroom tile or marble.

Low-iron glass puts your shower design on display, giving a near invisible and airy feel to your entire room.

What Is Tempered Shower Glass?

Tempered shower glass is the only glass permitted by law for bathroom shower installations. No wonder. Referred to as “safety glass”, instead of busting into large, sharp pieces, tempered glass shatters into small oval pebbles which greatly reduces the chance of serious cuts.

Tempered glass does not interfere with glass styles or choices and does not alter the look of clear, tinted or acid-etched glass patterns. Glass tempering is the last step in the glass fabrication process. After your custom glass panels are tempered at our manufacturer plant, your frameless shower is ready for installation.

It’s important that our clients understand basic properties of tempered glass to protect your frameless shower investment.

- Never attempt to cut or drill tempered glass as it will simply shatter.

- Extreme heat conditions such as fire will also cause tempered glass to shatter.

- Tempered glass does not protect glass clarity or prevent hard-water stains (factory or aftermarket glass protective treatments are recommended).

What are Typical Guidelines for Measuring?

- Measuring must be done after all finished wall material is in place.

- Measure each width or centerline (middle of threshold). Remember to allow for the body of the measuring tape.

- Measure maximum height available from top of tub deck or threshold to top of tile or fiberglass walls. This measurement will assist your Centennial representative in determining the most appropriate standard or custom height. Steam tight units are designed to fill the entire opening.

- Check all surfaces (including top of buttress if applicable) and walls for level. If any surface is out of level 3/8” or more, a tapered filler is recommended

What Does “Plum” and “Out of Plumb” Mean?

When surfaces are out of plumb or not level, there is a greater chance for water leakage through small openings between the wall and glass panel or shower frame. This can complicate the fabrication and installation process and potentially add to the cost and time of your project.

A level will tell you if your walls are plumb. To test the full-length of the wall use a six-foot (or longer) level. Smaller levels are less effective at determining wall outages.

If the header for you framed or semi-frameless shower door will run up to the ceiling, check the ceiling too. And, check the floor along the path where your sill will be affixed.

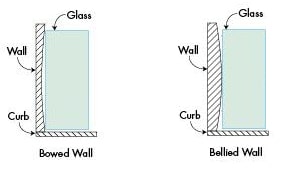

What if My Wall, Floor or Ceiling Isn’t Plumb?

When a Centennial Estimator visits to take final the measurements for your new shower project, all surfaces will be expertly measured and assessed.

About 75 percent of the homes we visit do not have perfectly straight walls so Centennial has skills and work-arounds to help trouble-shoot non-plumb surfaces.

Unlike framed showers, when a frameless glass shower panel meets an out of plumb wall, Centennial can custom cut the glass out of square so it lays flush against the out of plumb wall.

- Bow-shaped walls. Here we measure the glass to fit flush with the ends of the bow then seal the remaining gap in the middle using clear silicone caulking.

- Belly-shaped walls. Here we measure and fit for the tightest opening so the glass will set flush against the straightest part of the wall (usually along the middle). Gaps on the outer edges will then be sealed using clear silicone caulking.

How Long Will it Take to Manufacture My Shower?

Our tempered glass comes only from the highest-quality suppliers and we polish and perform all glass cutouts onsite. A big feature of dealing with Centennial estimators and installers is that we never become a middleman waiting on subcontractors to complete your shower.

When your glass is ready for installation, our Scheduling Coordinator will call and an installer can be typically be scheduled within days.

What is the Difference Between Acid-Etched Glass and Sandblasted Glass?

Acid etching is achieved using hexafluorosilicic acid (H2SiF6) which, when anhydrous, is colourless. The acid is prepared by dissolving silica in a mixture of hydrofluoric acid, quartz powder, calcium fluoride and concentrated sulfuric acid derived after heating. Acid-etched glass produces a true frosted look and is more economical than sandblasting.

Sandblasting utilizes a high-speed machine that bombards the glass panel with sand, walnut husks or other materials and offers versatility in creating design effects. First, homeowners can choose a level of glass opaqueness from light, medium or heavy. Sandblasting also makes it possible to “frost” sections of a glass shower, such as creating privacy strips or patterns

What is a U-Channel?

- Our U-channels fit 1/2″ (10mm) or 3/8″ (12mm) thick glass and are designed for frameless models only. Using thinner glass would require a full frame.

- We prefer using a deep U-channel that is 3/4″ tall. It offers a stronger bite on the glass. Some companies may use the smaller 3/8″ U-channels. Be sure to ask for a deep U-channel.

- Wet glaze means that silicone sealant is used to secure the glass panel into a U-channel. Standard U-channels are made for wet glaze application.

- There is also a U-channel designed for dry application. This U-channel is lined with a vinyl seal that grabs the glass. Minimal silicone sealant is applied first.

- When stronger support is needed we use a wet glaze U-channel application. For example, if a glass door will hinge to a fixed glass panel, the panel that supports the weight of the door needs to be fully sealed in the U-channel for security.

- If the extra support is not needed, a dry glaze U-channel application may reduce installation time, and the glass panel can more easily be removed if it ever gets damaged and needs replacement

- Wet and dry glaze U-channels cannot be used simultaneously when installing a glass shower since the U-channel lines around the shower glass panels won’t match and will create a visible difference that can’t be altered.

- For glass showers that are assembled with U-channels, instead of metal clips, a U-channel combined with a water sweep is added to the bottom of the shower door to create an even sight line with the U-channels bordering fixed glass panels.

What’s the Difference Between a Pivot Hinge and a Side-Mount Hinge?

Pivot Hinge Pros

- Pivot hinges are mostly attached at the far corners of the door, creating an uninterrupted frameless view.

- Pivot hinges that mount floor-to-ceiling can reduce the cost of glass fabrication.

- Pivot hinge doors carry the weight at the bottom of the door, and are thus very stabilized by a structurally sound floor.

Pivot Hinge Cons

- Pivot hinges can’t be sealed for extra water protection.

- If your pivot shower will not run floor-to-ceiling, then a metal header is required for the pivot to attach to a top structure. Ask a Centennial Glass representative for other options.

Side-Mount Pros

- Side-mount wall hinges avoid the need for a header or top support bar, which detracts from a frameless look.

- Side-mount hinges can be sealed to improve water tightness.

Side-Mount Cons

- Using side-mount hinges to mount a glass door to another glass panel (because no wall is available), may require a top header.

- Using glass-to-glass side-mount hinges means a second glass panel gets precision cuts to hold its end of the hinge. This adds to the total project cost.

Is a Pivot Hinge Shower Door Less Expensive than a Side-mount Hinge Shower Door?

A pivot hinge shower door can be less expensive, but not always. The versatility in which both hinges can be applied prevents labeling of these hardware products.

How one uses either hinge affects how much glass fabrication (Ottawa glass cutting and notching) is necessary. And this is really what drives price.

A pivot-hinge door secured to the ceiling and side-mount hinge secured to a wall do not differ in cost. If you were to secure a side-mount hinge to another glass panel, this configuration would require more glass fabrication work.